Stainless Steel Deep Drawing Process

Stainless Steel Deep Drawing Process

1Cr18Ni9Ti stainless steel is a metal material with strong strain, that is, the work hardening is serious in the process of deep drawing, showing the phenomenon of increased hardness and decreased plasticity, which is very obvious. Therefore, in the deep drawing process of the sheet of this type of material, after each deep drawing, annealing treatment is required to ensure the normal completion of the subsequent process.

1Cr18Ni9Ti stainless steel is a metal material with strong strain, that is, the work hardening is serious in the process of deep drawing, showing the phenomenon of increased hardness and decreased plasticity, which is very obvious. Therefore, in the deep drawing process of the sheet of this type of material, after each deep drawing, annealing treatment is required to ensure the normal completion of the subsequent process.

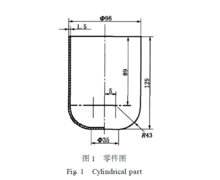

When the 1Cr18Ni9Ti workpiece is annealed, the heating temperature is generally 1150 to 1170 °C. In order to prevent oxide scale on the surface of the material, the heat treatment method of bright annealing is generally required. The high cost of annealing prolongs the production cycle and greatly reduces the production efficiency. For this reason, in the deep drawing of stainless steel cylindrical parts (Figure 1), a new process of canceling or changing the heat treatment method is adopted.

Selection of process parameters

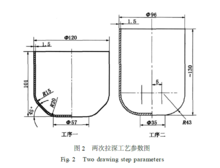

In accordance with the principle of reducing the number of deep-drawings as much as possible on the premise of ensuring the quality of the workpiece, two deep-drawing forming processes are adopted, and the deep-drawing coefficients are taken as m1 = 0.52 and m2 = 0.78 respectively. Figure 2 shows the process parameters of the two deep drawing steps. In order to reduce the aging time of material work hardening after the first deep drawing, the interval between two deep drawing operations should be shortened as much as possible, so as to achieve better drawing quality as a whole.

Deep Drawing die design

Improvement of the first set of deep drawing die concave and punch gap

First, take the gap between the concave and convex molds as Z = 1.2t (t is the nominal thickness of the sheet) for trial pulling. Because Z is too small and the degree of deformation is too large, not only the surface of the mold and the part is severely strained, but also serious thinning and cracks appear at the rounded corners of the tapered bottom of the part. Therefore, while improving the lubricating conditions and improving the surface quality of the mold, Z = t + 0.26t (t is the middle value of the allowable deviation of the thickness of the sheet metal) to re-adjust the gap between the concave and convex molds for the experiment and succeeded, very good The bottom fillet thinning and cracking issues are resolved. It is specially stated here that in order to reduce the deformation resistance during the second deep drawing and make the workpiece not easy to crack, the semi-finished product of the first deep drawing is designed as a cone bottom with an angle of 45°, the purpose of which is to improve the deep drawing deformation performance of the material.

Final drawing concave and punch gap adjustment

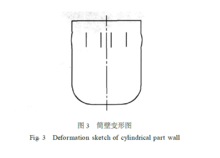

The maximum wall thickness of the semi-finished product in the first deep drawing is 2.3 mm. When the second set of drawing dies with a gap of 1.1 t between the concave and convex dies was used to finalize the work-hardened semi-finished product, the cylinder wall was deformed due to the strong demoulding due to the tight wrapping of the formed parts on the punch. It produced a convex belly (Figure 3). But the parts and the working surface of the mold are not strained.

To this end, while improving the lubrication conditions, the gap between the concave and convex die of the second set of drawing dies was adjusted according to Z = tmax +0.12t, so that the deformation of the cylinder wall of the part could be overcome.

Adjustment of heat treatment process

In order to eliminate the internal stress, the parts are finally annealed at a low temperature of 650 ℃

Selection and use of lubricants

In the whole production process, in addition to the reasonable adjustment of the concave and convex gaps, another important factor for the success of part drawing is the reasonable selection and use of lubricants. The following three lubricants are used together to ensure the smooth completion of the deep drawing process.

1. The contact surface of the part and the die is separated, and at the same time, the volatile substances in it can take away part of the heat generated during the drawing process.

2. G0124 vinyl chloride is another lubricant used in the deep drawing of stainless steel sheets. Coated on the surface of the blank or semi-finished product in contact with the working surface of the concave die to make up for the unevenness of the protective film formed by HB221 on the working surface of the concave die. Because the HB221 protective film is formed in the deep drawing process, its uniformity is difficult to guarantee, and it is inevitable to be uneven when smearing. It should be noted that both HB221 and G0124 cannot wait for the lubricant to dry and solidify on the coated surface before deep drawing, because this will affect the gap between the concave and convex molds, causing parts to crack or produce wrinkles and other defects.

3. No. 25 engine oil. It is mainly used for the second deep drawing, and it is applied to the contact surface between the punch and the forming part, so that the mold can be demolded smoothly, so as to avoid deformation and strain.

Summarize

After exploration, research and repeated experiments, the production method was finally successful. In the case of canceling the intermediate heat treatment, the stainless steel cylindrical parts with ideal surface quality were deep drawn and used for mass production. The life of the mold is also greatly extended, and good production benefits have been achieved. After two times of successful deep drawing of t = 115 mm stainless steel cylindrical parts, t = 018 mm and t = 1 mm stainless steel cylindrical parts have been deep-drawn three times, and basically successful. The only difference is that after the second deep drawing, a “box annealing” heat treatment at 860 °C is required instead of a “bright annealing” heat treatment.

Applicable materials

1. The deep drawn process relies on the balance of metal ductility and compression resistance. Suitable metals are: steel, copper, zinc, aluminum alloy, and other metals are prone to tearing and wrinkling during deep drawing.

2. Because the ductility of metal directly affects the production efficiency and quality of deep drawing, metal flakes are generally used as raw materials for processing.

Drawing Size

1. The inner diameter of the part formed by deep drawing should be controlled between 5mm-500mm (0.2-16.69in).

2. The longitudinal length of deep drawing is at most 5 times the inner diameter of the section of the part.

3. The longer the longitudinal length of the part, the thicker the metal sheet, otherwise there will be surface tearing during processing, because the thickness of the metal sheet will gradually decrease during the stretching process.