Quality Assurance for Precision Metal Components

Metal Stamping | Deep Drawing | Wire Forming

At ChinaCustomStamping, we recognize that exceptional quality is the foundation of success in today’s competitive manufacturing landscape. Our comprehensive quality control system ensures every component meets the highest standards before reaching our customers.

Our Multi-Stage Quality Assurance Process:

-

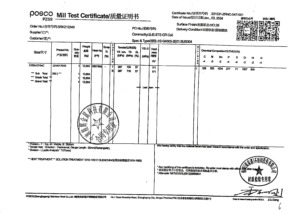

Stringent Raw Material Verification

-

All incoming materials undergo thorough inspection and testing

-

Material certifications and mill test reports are carefully reviewed

-

Chemical composition and mechanical properties are verified

-

-

In-Process Quality Monitoring

-

Dedicated QC technicians perform scheduled routing inspections

-

Random sampling at critical production stages

-

Real-time process parameter monitoring

-

-

Pre-Shipment Comprehensive Inspection

-

100% final dimensional verification

-

Functional testing where applicable

-

Surface finish and cosmetic evaluation

-

-

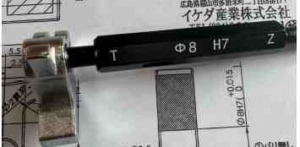

Advanced Measurement Capabilities

Our state-of-the-art inspection lab features:-

Digital precision measurement systems (Mitutoyo, Starrett)

-

Automated optical comparators

-

Coordinate measuring machines (CMM)

-

Surface roughness testers

-

Complete hardness testing laboratory

-

Salt spray testing facilities

-

Custom-designed inspection fixtures

-

Our Quality Control Methodology:

1. Dimensional Inspection Protocol

-

Measurement Environment: Controlled conditions at 20°C ±2°C with 50% ±5% relative humidity

-

Equipment Selection: Instruments matched to tolerance requirements (micrometers, height gauges, CMM)

-

Tolerance Standards: Strict adherence to customer specifications or applicable industry standards (ISO, ASME, DIN)

2. Surface & Visual Inspection

-

Conducted under standardized lighting conditions

-

Magnification up to 10× for critical surfaces

-

Surface finish verification per customer requirements

3. Mechanical Properties Testing

-

Hardness Testing: Rockwell, Brinell, and Vickers methods

-

Functional Testing:

-

Spring rate and deflection analysis

-

Fatigue life testing

-

Impact resistance evaluation

-

Bend testing to validate ductility

-

-

Microstructural examination when required

4. Material Certification

-

Full traceability from raw material to finished part

-

Material test reports available for all production lots

-

Compliance documentation for industry-specific requirements

Our Quality Commitment:

Each project is assigned a dedicated Quality Engineer who:

-

Reviews all customer quality requirements in detail

-

Develops customized inspection plans

-

Implements preventive quality measures

-

Maintains comprehensive documentation

All inspection data is systematically recorded in our quality management system and available to customers through:

-

First Article Inspection Reports (FAIR)

-

Statistical Process Control (SPC) data

-

Certificates of Conformance

-

Full dimensional inspection reports

We continuously invest in:

-

Employee training and certification programs

-

Equipment upgrades and technology adoption

-

Process improvement initiatives

By integrating rigorous quality controls at every manufacturing stage, we deliver metal components that consistently meet the most demanding specifications while maintaining competitive lead times and pricing.