Progressive Die Stamping

Progressive Die Stamping: The Ultimate Guide to Precision Metal Components by ChinaMetalStamping

Introduction

Progressive die stamping is a highly efficient and cost-effective metal forming process used to manufacture high-volume, precision metal components. As a leading Metal Stamping and Deep Drawing manufacturer in China, ChinaMetalStamping specializes in delivering superior-quality custom metal parts for various industries, including automotive, aerospace, electronics, medical devices, and more.

Progressive die stamping is a highly efficient and cost-effective metal forming process used to manufacture high-volume, precision metal components. As a leading Metal Stamping and Deep Drawing manufacturer in China, ChinaMetalStamping specializes in delivering superior-quality custom metal parts for various industries, including automotive, aerospace, electronics, medical devices, and more.

With decades of expertise in progressive die stamping, we utilize advanced machinery, cutting-edge technology, and skilled engineering to produce complex metal components with tight tolerances and exceptional consistency. Whether you require high-volume production runs or specialized short-run stamping, our services are tailored to meet your exact specifications.

In this comprehensive guide, we will explore:

- The benefits of this kind of stamping

- The materials used in the process

- A step-by-step breakdown of how progressive die works

- Industries that benefit from this manufacturing method

- Why ChinaMetalStamping is the best choice for your metal stamping needs

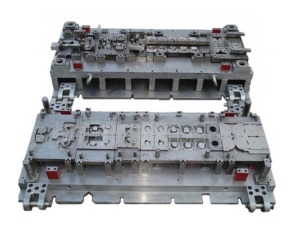

What Is Progressive Die Stamping?

It is a high-speed manufacturing process where a continuous strip of sheet metal is fed through a series of stamping stations, each performing a specific operation (such as punching, bending, coining, or blanking). With each press stroke, the metal strip advances through the die, progressively forming the final part.

Unlike traditional single-stage stamping, this stamping combines multiple operations into one seamless process, significantly reducing production time and costs while maintaining superior accuracy.

Key Features of progressive die stamping :

- Multiple operations in one pass – Reduces handling and secondary processing.

- High-speed production – Ideal for large-volume manufacturing.

- Minimal material waste – Optimized nesting reduces scrap.

- Tight tolerances – Ensures precision and consistency.

- Cost-effective for long runs – Lower per-unit cost compared to other methods.

Benefits of Choosing Progressive Die Stamping from ChinaMetalStamping

As a professional Stamping manufacturer in China, we provide unmatched advantages for businesses seeking high-quality, precision-engineered metal components.

1. Reduced Labor Costs

Progressive die stamping automates multiple operations, minimizing manual intervention and lowering labor expenses.

2. High Production Output

Our advanced stamping presses operate at high speeds, producing thousands of parts per hour with consistent quality.

3. Long Run Lengths & Scalability

Whether you need prototypes, medium runs, or mass production, our progressive die stamping process is optimized for scalability.

4. Minimal Material Scrap

Efficient nesting and optimized die design ensure maximum material utilization, reducing waste and cost.

5. Fast Setup & Changeover Times

Our dies are designed for quick installation and adjustments, allowing faster transitions between production runs.

6. Tight Tolerances & Superior Precision

With precision-engineered dies and CNC-controlled presses, we achieve tolerances as tight as ±0.001 inches, ensuring flawless part consistency.

7. Versatility in Design & Material Options

From simple brackets to complex multi-stage components, our progressive die stamping accommodates intricate designs.

Materials Used in Progressive Die Stamping

At ChinaMetalStamping, we work with a wide range of metals to meet diverse industry requirements. Our material selection includes:

| Material | Key Properties | Common Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, excellent conductivity | Aerospace, automotive, electronics |

| Stainless Steel | High strength, corrosion resistance, durability | Medical devices, food processing, automotive |

| Copper | Superior electrical & thermal conductivity | Electrical components, connectors, busbars |

| Brass | Machinability, corrosion resistance, aesthetic appeal | Plumbing fixtures, musical instruments |

| Nickel Alloys | High-temperature resistance, corrosion resistance | Aerospace, chemical processing |

| Titanium | High strength-to-weight ratio, biocompatibility | Medical implants, aerospace components |

| Cold-Rolled Steel | Excellent formability, smooth surface finish | Automotive panels, appliances |

We also work with specialty alloys such as:

- Monel® (corrosion-resistant nickel alloy)

- Hastelloy® (high-performance nickel-molybdenum alloy)

- Kovar® (low thermal expansion alloy)

- Inconel® (superalloy for extreme environments)

Our engineering team helps select the best material based on strength, ductility, weldability, and machinability for your specific application.

The Progressive Die Stamping Process: Step-by-Step

Step 1: Design & Tooling Development

Our engineers use CAD/CAM software to design custom dies tailored to your part specifications.

Step 2: Material Feeding

A coil of sheet metal is fed into the stamping press, where it moves through multiple stations.

Step 3: Progressive Stamping Operations

Each station performs a different operation:

- Piercing (creating holes)

- Blanking (cutting the part outline)

- Bending (forming angles)

- Coining (precision shaping)

Step 4: Final Ejection

The finished part is separated from the metal strip, ready for secondary processing (if required).

Step 5: Quality Inspection

Each component undergoes rigorous dimensional checks, surface inspections, and functional testing to ensure compliance with industry standards.

Industries Served by ChinaMetalStamping

Our progressive die stamping solutions cater to a wide range of industries:

1. Automotive

- Brackets, connectors, fuel system components

- Electrical contacts, sensor housings

2. Aerospace & Defense

- Precision aircraft fittings, engine components

- Missile & satellite parts

3. Electronics & Electrical

- Heat sinks, shielding components

- Battery contacts, relay terminals

4. Medical Devices

- Surgical instruments, implantable components

- Diagnostic equipment parts

5. Consumer Appliances

- Washer/dryer components, refrigerator parts

- HVAC system brackets

6. Industrial Machinery

- Hydraulic system parts, gear components

- Conveyor system brackets

Why Choose ChinaMetalStamping for Progressive Die Stamping?

✅ 30+ Years of Expertise – Trusted manufacturer with a proven track record.

✅ Advanced Stamping Technology – State-of-the-art presses and CNC machinery.

✅ Custom Die Design & Tooling – Tailored solutions for complex geometries.

✅ Strict Quality Control – ISO-certified processes for defect-free parts.

✅ Competitive Pricing – Cost-effective solutions without compromising quality.

✅ End-to-End Services – From prototyping to full-scale production.

Additional Value-Added Services

To ensure your parts are ready for assembly, we offer:

- Deburring & Surface Finishing

- Plating (Zinc, Nickel, Gold, etc.)

- Anodizing & Powder Coating

- Heat Treatment (Annealing, Tempering)

- Welding & Assembly

Conclusion: Partner with ChinaMetalStamping for Superior Progressive Die Stamping

As a leading Progressive Die Stamping manufacturer in China, ChinaMetalStamping combines precision engineering, advanced technology, and cost-effective manufacturing to deliver high-quality metal components for global industries.

Whether you need prototype development, short-run production, or large-scale manufacturing, our team is ready to provide custom solutions tailored to your exact requirements.

Contact us today for a free consultation and quote! Let’s bring your metal component designs to life with precision, efficiency, and reliability.

Trackbacks & Pingbacks

[…] Cutting, Precision Stamping, Progressive die stamping,CNC Bending, CNC Milling, CNC Turning, Threading, Riveting, Drilling, CNC Punching, Die Casting, […]

Comments are closed.