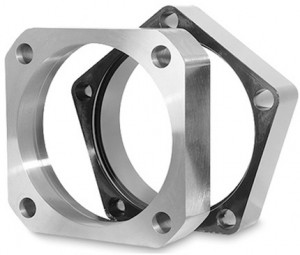

CNC Machining

At ChinaCustomStamping, we take great pride in being a trusted and professional manufacturer of CNC Machining solutions. With our cutting-edge technology, highly skilled team, and unwavering commitment to quality, we deliver precision-engineered components that meet and exceed industry standards. In this post, we will explore the advantages of CNC machining and why ChinaCustomStamping is the ideal partner for your manufacturing needs.

CNC Machining is the abbreviation of mechanical processing. It refers to the process of removing materials by mechanical precision machining.Computer controll machining refers to the use of CNC equipment for machine workers, which include machining centers, car milling centers, electrical discharge wire cutting equipment, thread cutting machines, etc.The machining processes to make workpiece in a continuous way, which is suitable for large quantities and complex parts.

CNC Machining Services

When your project requires CNC machining services, you need an experienced manufacturer who can handle large quantities of orders and can quickly invest in your project. We know your request. Our machining experts are very clear that we can use strict tolerances. Our team has decades of experience in mobile phone and computer numerical control.

- (CNC) machines, including:

- CNC Lathes

- CNC vertical machining center

- CNChorizontal boring Mills

- CNC Gantry Mills

Why Our Services

We know that customers have many resources to process projects, but our goal is to provide services that meet all your needs. Our facilities include larger metalworking machinery than most metal processing workshops.

Our processing equipment and experienced technology enable us to become your all-round source of processing. Whether your processing project is simple or complex, we have skilled workers, equipment and efficiency to meet your goals and time. CNCT processing services include:

- Multi task steering equipment, vertical and horizontal milling capability

- Fixture design, construction and maintenance

- Tooling short run and prototype capabilities

- Flexible production quantity to meet your needs

Production ability

| Main Product | Machining parts, Precision mechanical components, Precision milling parts |

| Main Material | Brass, Copper, Carbon steel, Stainless steel, Steel alloy, Aluminum alloy |

| Surface Treatment | Zinc plating,Nickel plating,chromate plating,anodize as per customer’s requirement |

| The Most Precise Tolerances That Reetech Can Process | 1)Shaft diameter below 6mm and maximum pore size tolerance up to 0.003mm, 2)Shaft diameter larger than 6mm and pore size tolerance is 0.005mm, 3)Linearity below 100mm distance etc, tolerance is up to 0.005mm, 4)100mm or more distance linear tolerance is up to 0.01mm, 5)A form tolerance is up to 0.003 – 0.005mm, 6)Position tolerance is up to 0.01mm. |

| Production Equipment | 1)Machining Center; 2)CNC Lathe; 3)CNC Milling Machine; 4) Precision Cutting Machine |

| Measuring Instruments and Equipment | 1)micrometer, 2)smooth plug gauge, 3)thread gauge, 4) Image measuring instrument, 5) Coordinate Measuring Machine, 6) Roughness tester, 7) routine inspection of calipers |

| Preferred Drawing Formats |

JPEG, PDF,CAD,IGS,STP,and So on |

| Preferred Industries | 1) Communication Equipments 2) Medical Equipments 3) Photoelectricity Equipments 4) Auto Industry 5) Mechanical Equipments 6) Other customized Parts |

We are Specialized in hardware lathe processing, non-standard parts, cutting processing, precision hardware parts, mechanical parts, precision machining, stainless steel parts processing, stainless steel processing, mechanical processing, and mechanical parts manufacturing.

We produce over 1000 types of products, which are widely used in various fields such as household appliances, instruments and meters, communication, aerospace, computers, mechanical equipment, automotive parts, etc.

Our product quality is in a leading position among our domestic peers. The raw materials currently produced include stainless steel, iron, copper, aluminum, etc. They are mainly skilled in cutting and processing stainless steel parts, internal and external thread processing, as well as lathe processing of various copper, aluminum, and iron parts