Sheet Metal Deep Drawn

Sheet Metal Deep Drawn

Sheet Metal Deep Drawn stands out as a widely utilized technique in the realm of sheet metal forming. Besides its application across various industries, it finds significant use in the automotive sector for crafting car body components.

Definition of the Process:

Deep drawing entails a forming process that transpires under a blend of tensile and compressive conditions. It involves transforming a flat sheet metal blank into a hollow body open on one side or reshaping a hollow body into one with a reduced cross-section. This process is subdivided into three categories:

– Deep drawing with tools

– Deep drawing with active means

– Deep drawing with active energy

Typically, in the automotive realm, deep drawing is conducted utilizing rigid tools.

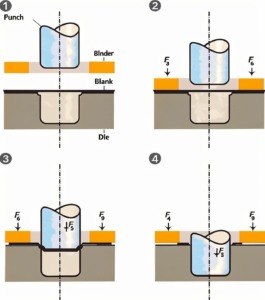

Visual Representation of the Sheet Metal Deep Drawn

The illustration showcases the deep drawing process, encompassing rigid tools such as a punch, die, and binder. During deep drawing, the plate holder closes post-insertion of the metal sheet blank. Subsequently, the sheet gets secured between the die and the binder, which hinders wrinkles from forming beneath the binder by regulating sheet flow. The punch stretches the sheet over the die radius for shaping within the die, with the necessary punch force escalating gradually up to the lower dead center of the punch.

In contrast to pure deep drawing where there’s no thickness reduction in the sheet metal, stretch forming achieves shaping through thinning the sheet metal thickness alone. Stretch forming is predominantly employed for crafting mildly curved parts with limited draw depth, like roofs and doors.

Complex car body part production often involves a blend of stretch and deep drawing methods in practice. It’s pivotal to stretch the sheet metal optimally without pushing it to its material limits to avert issues such as splits or wrinkles.

Constructing the body of a car typically necessitates around 300 to 400 sheet metal components. To fabricate top-quality sheet metal parts tailored for specific purposes, specialized software simulates the entire deep drawing process.

Our Deep Drawing Services

|

Item Name : OEM Custom deep drawing parts

|

|

|

Material: carbon steel(cold rolled steel sheet,galvanized steel sheet or tube),stainless steel,copper,brass,aluminum,etc

|

|

|

Tolerance丨Surface Roughness: +/-0.005 – 0.01mm 丨 Ra0.2 – Ra3.2(Custonize avaiable)

|

|

|

Surface Treatment: Polishing, general/hard/color oxidation, surface chamfering, tempering, etc.

|

|

|

Testing Equipment:CMM/Tool microscope/multi-joint arm/Automatic height gauge/Manual height gauge/Dial gauge/Roughness measurement

|

|

|

Drawing Formats: PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF

|

|

|

Special specifications can also be produced according to drawings and samples.

|

|