Blank Layout for Stamped Parts

Optimizing Blank Layout for Stamped Parts

Introduction to Blank Layout in Stamping

Blank layout, represents a fundamental process in metal stamping operations that significantly impacts production efficiency, material utilization, and product quality. As a professional metal stamping and deep drawing manufacturer in China, ChinaCustomStamping has mastered the art and science of blank layout optimization to deliver cost-effective solutions for clients worldwide.

The strategic arrangement of parts on sheet metal before the punching process might appear simple at first glance, but it actually involves complex considerations of geometry, material properties, and production requirements. Proper blank layout can mean the difference between profitable operations and wasteful production, particularly in high-volume manufacturing environments where material costs often constitute more than 60% of total production expenses.

Fundamental Classification of Blank Layout Methods

1. Waste-Based Classification System

Industry professionals typically categorize blank layout methods based on waste generation patterns:

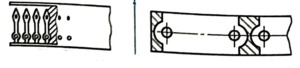

a) Layout with Waste:

This conventional approach maintains substantial margins between parts and along strip edges. While it generates more scrap material, it offers superior dimensional accuracy and extended mold life. The protective margins help absorb uneven stresses during punching, preventing premature die wear. ChinaCustomStamping often recommends this method for precision components where tight tolerances are critical.

b) Minimal-Waste Layout:

A transitional approach that strategically reduces but doesn’t completely eliminate margins. This balances material savings with acceptable quality levels, particularly suitable for components with moderate precision requirements.

c) Waste-Free Layout:

The most material-efficient method eliminates all margins between parts. While maximizing material utilization (often achieving over 90% efficiency), it subjects dies to uneven lateral forces that can accelerate wear. Our engineers at ChinaCustomStamping carefully evaluate product specifications before implementing this method, typically reserving it for non-critical components.

2. Geometric Arrangement Classification

The second classification system examines the spatial organization of parts on the material, with each pattern serving specific geometric requirements:

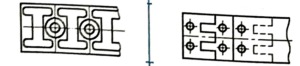

a) Straight Layout:

The simplest arrangement where parts align in straight rows and columns. Ideal for square or rectangular components, this method offers easy implementation but may not optimize material usage for complex shapes.

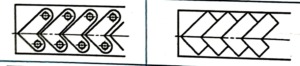

b) Angled Layout:

Parts rotate at an angle (typically 30°-60°) to better fit irregular contours. ChinaCustomStamping frequently employs this for L-shaped, T-shaped, or elliptical components where straight alignment would create excessive waste.

c) Paired Straight Layout:

Mirror-image arrangement where parts interlock like puzzle pieces. Particularly effective for T-shaped, arrow-shaped (↑形), or triangular components, this method can significantly improve material utilization.

d) Paired Angled Layout:

Combines rotation with mirroring for complex shapes like S-shaped or trapezoidal parts. Requires advanced nesting software but can achieve remarkable material savings.

e) Mixed Layout:

Simultaneously nests different parts from the same material thickness. ChinaCustomStamping utilizes this for product families where components share material specifications but have varying geometries.

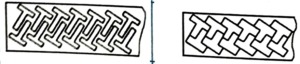

f) Multi-row Layout:

High-density arrangement for mass production of simple geometric shapes (circles, hexagons, etc.). Enables extremely high throughput but demands precision in strip feeding.

g) Edge-Trimming Layout:

Specialized method for elongated parts where the strip’s edges become part of the component. Requires careful design to maintain dimensional stability.

Technical Considerations in Blank Layout Design

Material Utilization Optimization

The primary economic driver in blank layout design remains material efficiency. ChinaCustomStamping’s engineering team approaches this challenge through:

-

Advanced Nesting Algorithms: Utilizing CAD/CAM software with genetic algorithms that test thousands of potential arrangements to identify optimal patterns.

-

Grain Direction Management: Aligning part geometries with the material’s rolling direction when mechanical properties are anisotropic.

-

Scrap Minimization Techniques: Implementing strategies like:

-

Shared cutting lines between adjacent parts

-

Strategic placement of pilot holes in scrap areas

-

Designing scrap skeletons that can be recycled or reused

-

-

Dynamic Nesting for Mixed Production: When handling multiple part numbers, our systems dynamically adjust layouts to maximize overall material utilization across all products.

Quality and Precision Factors

While material savings are important, they must not compromise product quality. Key considerations include:

-

Margin Design: Determining the minimum necessary spacing between parts and strip edges based on:

-

Material type and thickness

-

Part geometry complexity

-

Required edge quality

-

Tooling considerations

-

-

Deformation Control: Anticipating and compensating for material deformation during punching, particularly in high-speed operations.

-

Strip Guidance Requirements: Ensuring adequate material for reliable feeding through progressive dies, especially in automated high-speed presses.

Tooling and Production Implications

Blank layout decisions profoundly impact tool design and production efficiency:

-

Die Life Optimization: Balanced layouts distribute wear evenly across cutting edges, extending tool life. ChinaCustomStamping’s tooling engineers carefully analyze stress distribution in proposed layouts.

-

Press Selection Implications: Layout affects required press tonnage, shut height, and bed size. Our production planning integrates these factors early in the design process.

-

Automation Compatibility: Modern automated feeding systems require specific strip designs that our engineers incorporate into layout planning.

Advanced Techniques in Blank Layout

1. Parametric Nesting Systems

ChinaCustomStamping has developed proprietary parametric nesting systems that automatically adjust layouts based on real-time inputs:

-

Material coil width variations

-

Order quantity fluctuations

-

Priority-based production scheduling

-

Quality requirement changes

2. AI-Assisted Layout Generation

Our R&D team has implemented machine learning systems that:

-

Analyze historical production data to predict optimal layouts

-

Continuously improve nesting algorithms based on actual production results

-

Automatically flag potential quality issues in proposed layouts

3. Multi-Material Optimization

For projects involving different materials or thicknesses, we’ve developed advanced optimization techniques that:

-

Coordinate blanking across multiple production lines

-

Optimize material ordering to minimize total waste across all materials

-

Balance production efficiency with material utilization

Case Studies: ChinaCustomStamping’s Practical Applications

Automotive Component Production

In a recent project for electric vehicle battery components, our engineers achieved:

-

18% material savings through optimized angled paired layout

-

22% increase in press productivity via improved strip design

-

Maintained 99.7% dimensional accuracy despite reduced margins

Electronics Enclosure Manufacturing

For a high-volume electronics enclosure:

-

Implemented mixed layout with three different components

-

Achieved 93% material utilization

-

Reduced tool wear by 15% through balanced cutting force distribution

Appliance Parts Production

Developed a innovative edge-trimming layout that:

-

Eliminated separate trimming operations

-

Reduced material waste by 27%

-

Shortened production cycle time by 18%

Future Trends in Blank Layout Technology

As a forward-looking manufacturer, ChinaCustomStamping is investing in several emerging technologies:

-

Cloud-Based Nesting Systems: Enabling real-time layout optimization across multiple factories and material suppliers.

-

Digital Twin Integration: Creating virtual models that simulate how layout choices affect the entire production chain.

-

Sustainable Material Practices: Developing layouts that optimize for recyclability and minimal environmental impact.

-

Additive Manufacturing Hybrid Approaches: Combining traditional stamping with 3D printed features to enable even more material-efficient designs.

Conclusion

Blank layout optimization represents a critical competitive advantage in modern metal stamping operations. As demonstrated by ChinaCustomStamping’s extensive experience, thoughtful layout design can simultaneously achieve material savings, quality improvement, and production efficiency. The field continues to evolve with advances in computational power, AI algorithms, and manufacturing technology, offering ever-greater opportunities for optimization.

Manufacturers seeking to maximize their stamping operations’ efficiency should consider partnering with experienced specialists like ChinaCustomStamping, where our expertise in blank layout optimization combines with state-of-the-art manufacturing capabilities to deliver superior results. From simple straight layouts to complex mixed arrangements, our engineering team possesses the knowledge and tools to develop optimal solutions tailored to each product’s unique requirements.

By mastering both traditional principles and cutting-edge technologies in blank layout design, ChinaCustomStamping continues to set industry standards for efficient, high-quality metal stamping production in China’s competitive manufacturing landscape.