Pressure Center Calculation

Pressure Center Calculation in Metal Stamping Dies

Introduction

ChinaCustomStamping is a professional metal stamping and deep drawing manufacturer in China, specializing in precision tooling and high-volume production. One of the critical aspects of die design is ensuring the pressure center (CoP – Center of Pressure) aligns with the press machine’s slide center. Misalignment can lead to eccentric loading, uneven wear on guide components, and even die failure. This article provides an in-depth analysis of pressure center calculation methods for both simple and complex stamping dies.

What is the Pressure Center?

The pressure center is the point where the resultant force of the punching load acts. In progressive dies or blanking dies, accurately determining this point ensures:

-

Balanced force distribution across the die.

-

Reduced deflection of punches and die components.

-

Extended tool life by preventing uneven wear.

-

Improved part quality by avoiding uneven cutting clearance.

If the pressure center deviates from the press slide center, it causes side thrust, leading to:

-

Premature wear on guide pins and bushings.

-

Misalignment in punch-die clearance.

-

Increased risk of chipped cutting edges or broken punches.

Calculating Pressure Center for Simple Geometries

For simple shapes (e.g., circles, rectangles, straight lines), the pressure center coincides with the geometric center.

1. Straight-Line Punching

-

The pressure center is at the midpoint of the line.

-

Example: A 100mm straight edge has its pressure center at 50mm.

2. Circular & Arc Punching

For an arc , the pressure center is calculated as:

Where:

-

= Arc radius

-

= Half of the arc’s included angle (in degrees)

Calculating Pressure Center for Complex Geometries

For irregular shapes or multi-punch dies, the analytical method (moment equilibrium method) is used.

Step-by-Step Calculation:

-

Divide the contour into basic segments (lines, arcs).

-

Determine each segment’s length () and centroid coordinates (xi,yi).

-

Lines: Centroid = midpoint.

-

Arcs: Use the arc pressure center formula.

-

-

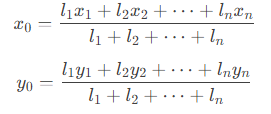

Apply the moment equilibrium theorem:

Example: Multi-Punch Die

For dies with multiple punches :

-

Calculate each punch’s pressure center.

-

Use the same formula, where = cutting perimeter of each punch.

Practical Considerations in Die Design

-

Symmetrical Parts → Pressure center = geometric center.

-

Asymmetrical Parts → Must be calculated analytically.

-

Progressive Dies → Pressure center shifts; ensure the final stage aligns with the press center.

-

Finite Element Analysis (FEA) can validate calculations for high-precision dies.

Conclusion

Accurate pressure center calculation is essential for die longevity, part quality, and press machine health. ChinaCustomStamping leverages advanced CAD/CAM and simulation tools to ensure optimal die designs for metal stamping, deep drawing, and precision blanking.

By following the analytical method, manufacturers can prevent eccentric loading, reduce maintenance costs, and enhance production efficiency.

For custom stamping solutions, contact ChinaCustomStamping – your trusted partner in high-performance metal forming.