Precision Custom Stamping

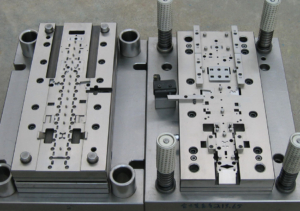

Precision custom stamping is a material processing method developed on the basis of ordinary stamping technology. It is achieved by improving the guiding accuracy, reducing the gap between the convex and concave dies, increasing the reverse pressure and the V-ring blank holder. Under the condition of the three-way compressive stress state, the process of precision stamping or precision stamping combined with other forming processes can be realized to obtain precision stamping parts.

Precision stamping requires high precision of stamping parts. In the process of processing and production, when stamping coils or forming, it is necessary to consider the appropriate technical matching of precision punches, molds, materials, lubricants, etc., and the requirements are high.

Custom Precision Metal Stamping

As a professional stamping manufacturer in china,our custom engineered metal stamping services will allow us to assist you in the design and re-engineering of your custom engineered metal stamping parts.

Including solidworks, logopress, and more; our engineered metal stamping services provides you with maximum precision manufacturing ability under low cost.

Stamping Range:

- Aluminum Stampings

- Automotive Stampings

- Metal Stampings

- Fourslide and Multislide Stampings

- Stainless Steel Stampings

- Long Run, High Speed Stamping

- Progressive Die Stampings

What need for quotation

- Drawing or sample. If drawing,please indicate all dimension and tolerance

- Material.Please advise details of material,even same material, there are many kinds at different price,such as SS304,316,430 and so on

- Finish. What kind of finish you need,such as polish,plating,coating and so on

- Quantity. This is also important factor to influence the price.Small quantity, the production cost will be higher.

- Application. For example, where will your items to be used.This is very important to deceide how to produce this item and how to control the quality.

- Other information. If you have any additional information, please advise us too.