Reduce Blanking Force

Process Measures to Reduce Blanking Force in Metal Stamping

Introduction

In metal stamping, blanking is a critical process used to cut sheet metal into desired shapes. However, high blanking forces can limit the capability of smaller-tonnage presses, increase tool wear, and cause excessive vibration. To address these challenges, manufacturers employ various process measures to reduce blanking force, enabling the production of larger and thicker parts with lower energy consumption. China Custom Stamping, a professional metal stamping and deep drawing manufacturer in China, utilizes advanced techniques such as step blanking, inclined cutting edges, and hot blanking to optimize production efficiency and tool life.

In metal stamping, blanking is a critical process used to cut sheet metal into desired shapes. However, high blanking forces can limit the capability of smaller-tonnage presses, increase tool wear, and cause excessive vibration. To address these challenges, manufacturers employ various process measures to reduce blanking force, enabling the production of larger and thicker parts with lower energy consumption. China Custom Stamping, a professional metal stamping and deep drawing manufacturer in China, utilizes advanced techniques such as step blanking, inclined cutting edges, and hot blanking to optimize production efficiency and tool life.

This article explores these key methods in detail, discussing their mechanisms, advantages, limitations, and practical applications in industrial manufacturing.

1. Step Blanking (Progressive Punching with Staggered Heights)

1.1 Concept and Mechanism

Step blanking involves designing a multi-punch die where punches are arranged at different heights in a staggered (step-like) configuration. This ensures that the maximum blanking force does not occur simultaneously across all punches, thereby reducing peak load on the press.

1.2 Advantages

-

Reduced Peak Force: By distributing the load over time, the press operates more smoothly.

-

Minimized Vibration: Step blanking decreases machine vibration, improving precision and tool life.

-

Protection of Small Punches: In multi-hole blanking, shorter punches for smaller holes prevent breakage caused by material flow-induced lateral forces.

1.3 Design Considerations

-

Height Difference (H):

-

For thin materials (t < 3mm), H ≈ material thickness (t).

-

For thick materials (t > 3mm), H ≈ t/2.

-

-

Application in Progressive Dies: Punches without pilot pins are often made shorter to avoid interference.

*Figure 1: Step blanking configuration (H = height difference between punches)*

2. Inclined Cutting Edge (Oblique Shearing)

2.1 Principle of Operation

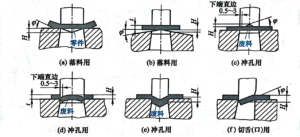

Unlike conventional flat-edge blanking (where the entire cutting edge engages simultaneously), inclined cutting edges introduce an angled or wave-like profile to the die or punch. This ensures gradual shearing, significantly reducing instantaneous blanking force.

2.2 Types of Inclined Edge Designs

(Refer to Figure 2 for configurations)

-

For Blanking (Punching Out Parts):

-

Flat punch + Inclined die → Ensures a flat workpiece surface.

-

-

For Piercing (Punching Holes):

-

Flat die + Inclined punch → Typically designed with symmetrical peaks to avoid lateral deflection.

-

-

Special Cases (Notching/Cutting Tongues):

-

Single-sided inclined edges are used for partial cutting operations.

-

2.3 Advantages and Challenges

-

Advantages:

-

Up to 50–70% reduction in blanking force compared to flat-edge tools.

-

Suitable for large parts (multiple peaks can be used to distribute force).

-

-

Challenges:

-

Complex manufacturing & maintenance: Inclined edges are harder to grind and align.

-

Dimensional accuracy: Workpieces may exhibit slight warping.

-

2.4 Key Design Parameters

| Material Thickness (*t*) | Blade Height (H) | Angle (φ) |

|---|---|---|

| < 3 mm | 2*t* | < 5° |

| 3–10 mm | *t* | < 8° |

3. Hot Blanking (Heated Shear Cutting)

3.1 Process Overview

Heating the material before blanking reduces shear strength, allowing lower press tonnage. This method is particularly effective for thick or high-strength materials (e.g., stainless steel, titanium).

3.2 Benefits and Limitations

-

Pros:

-

Drastically lowers required force.

-

Extends die life by reducing wear.

-

-

Cons:

-

Requires precise temperature control.

-

May introduce oxidation or thermal distortion.

-

4. Comparative Analysis of Force Reduction Methods

| Method | Force Reduction | Precision | Tool Complexity | Best Applications |

|---|---|---|---|---|

| Step Blanking | Moderate | High | Medium | Multi-hole parts |

| Inclined Edge | High | Medium | High | Large/flat parts |

| Hot Blanking | Very High | Low-Med | Very High | Thick/hard materials |

5. Industry Applications by China Custom Stamping

As a leading metal stamping and deep drawing manufacturer in China, China Custom Stamping implements these techniques to:

-

Optimize press utilization (enabling smaller machines to handle larger parts).

-

Enhance tool longevity (reducing wear via force distribution).

-

Improve part quality (minimizing burrs and distortion).

Case studies include:

-

Automotive components (brackets, panels) using step blanking.

-

Electronics enclosures with inclined-edge piercing.

-

Aerospace parts produced via hot blanking.

Conclusion

Reducing blanking force is essential for efficient, cost-effective stamping operations. By adopting step blanking, inclined cutting edges, and hot blanking, manufacturers like China Custom Stamping achieve superior performance in precision metal forming. Future advancements may focus on adaptive tooling systems and AI-driven force optimization to further push the boundaries of stamping technology.