Deep Drawing

Deep Drawing

The stamping processing method of changing the panel blank into an open hollow part by means of a die is called deep drawing. The drawing process is also known as drawn, calendaring, extension, stretching and so on. It is one of the main stamping processes, which is widely used. The cylindrical, stepped, tapered, square, spherical and various irregular thin-wall parts can be obtained by using the deep drawn stamping method.

The stamping processing method of changing the panel blank into an open hollow part by means of a die is called deep drawing. The drawing process is also known as drawn, calendaring, extension, stretching and so on. It is one of the main stamping processes, which is widely used. The cylindrical, stepped, tapered, square, spherical and various irregular thin-wall parts can be obtained by using the deep drawn stamping method.

The precision of drawing parts is related to many factors, such as the mechanical property and thickness of materials, die structure and die precision, the number of processes and the sequence of processes. Generally, the manufacturing accuracy of drawing parts is not high, and the appropriate accuracy is below IT11.

There are many kinds of drawing parts. According to the change of wall thickness before and after forming, the drawing can be divided into two types: variable and constant thin drawing. At the same time, due to the characteristics of the drawing itself, the upper and lower walls of the drawing part are appropriately thinner, and the thickness after drawing is about (1.2~0.6) t. In addition, the outer wall or flange surface of the part drawn for several times will generally leave the marks produced in the drawing process.

What is Deep drawing

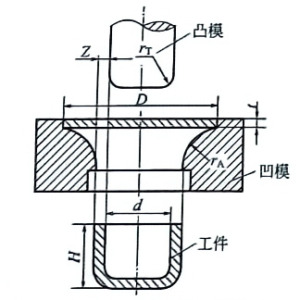

The die for drawing is mainly composed of convex die, concave die and blank holder. Different from the blanking, the working parts of the male and female dies have no sharp cutting edges, but a certain round corner, and the gap is slightly larger than the thickness of the plate. A circular blank with a diameter D and a thickness t is drawn by a drawing die to obtain an open cylindrical work-piece having an outer diameter d and a height H.

In the drawing process, the center part of the blank becomes the bottom of the simple part, which is basically non-deformable and is a non-deformable area; The flange part of the blank is the main deformation zone. The drawing process is essentially the process of gradually transferring the material of the rough flange part to the cylinder wall

Material of drawing parts

The material used for drawing parts shall have good plasticity, small yield ratio σ s/σ b, large plate thickness directivity coefficient and small plate plane directivity coefficient. The smaller the yield ratio σ s/σ b is, the bigger the allowable ultimate deformation is, and the better the drawing performance is. For example, for yield ratio σ s/σ b=0.57 of mild steel, the minimum drawdown coefficient for one draw is m=0.48~0.50; The σ s/σ b of 65Mn steel=0.63, and the minimum drawing coefficient of one drawing is m=0.68~0.70. Therefore, according to relevant material standards, the yield ratio of steel plates for drawing shall not be greater than 0.66.

The plate thickness directivity coefficient and the plate plane directivity coefficient reflect the anisotropic property of the material. When the plate thickness directivity coefficient is large and the plate plane directivity coefficient is small, the deformation of the material in the width direction is easier than the deformation in the thickness direction, and the plate plane performance difference is small. The material is not easy to thin or crack during the drawing process, so it is beneficial to the drawing forming.

Structure Workmanship of Drawn Parts

1.Drawn parts shall be as simple and symmetrical as possible and can be formed in one time,

2. Generally, the wall thickness tolerance or thinning requirement of drawing parts shall not exceed the change rule of wall thickness of drawing process. Based on statistics,the maximum thickness increase of the cylinder wall of the constant thickness drawing process is about (0.2~0.3) t (t is the thickness of the sheet material), and the maximum thinning is (0.1~0.18) t

3.When the deformation degree of the part in one drawing is too large, in order to avoid cracking, it is necessary to use multiple drawings. At this time, under the premise of ensuring the necessary surface quality, the inner and outer surfaces shall be allowed to have possible traces in the drawing process.

4.On the premise of ensuring the assembly requirements, it is allowed that the side image of the drawn part has a certain slope.

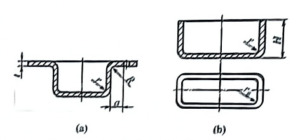

5.When there are holes on the bottom or flange of the drawing part, the distance from the hole edge to the side wall shall meet a ≥ R+0.5t (or r+0.5t),As shown in the figure below.

6.The fillet radius at the bottom and wall of the drawing part, flange and wall, four corners of the rectangular part, etc. shall meet the following requirements: r ≥ t, R ≥ 2t,

rg≥3t。 Otherwise, the shaping process shall be added. For one shaping, the semidiameter of the fillet can be r ≥ (0.1~0.3) t, R ≥ (0.1~0,3) t.

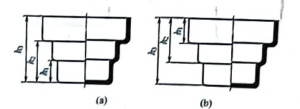

7.The radial dimension of the drawing part shall be only marked with the overall dimension or internal dimension, and shall not be marked with the internal and external dimensions at the same time. For the drawing parts with steps, the dimension indication in the height direction shall be based on the bottom of the drawing parts, as shown in the following figure. If the upper part is taken as the benchmark, the height and dimension cannot be guaranteed easily.

Advantages of Deep Drawing

Deep drawing, a centuries-old process, offers numerous benefits and precision. Here are some of its key advantages:

- Seamless Construction: Deep drawing creates uniform, seamless shapes, minimizing potential weak spots in the final product.

- Enhanced Strength: In certain instances, the deformation process hardens the material, boosting the strength of the parts.

- Consistent Quality: Deep drawn parts maintain a high level of uniformity throughout the production run.

- Quick Cycle Times: Presses used in deep drawing can operate rapidly, making it an efficient method for producing large quantities of parts.

- Labor Cost Savings: Automation in deep drawing significantly reduces labor expenses.

- Minimal Maintenance: Deep draw setups require less maintenance compared to alternative processes.

- Streamlined Assembly: Deep drawing can produce shapes with closed ends, minimizing or eliminating the need for secondary processes like fabrication or welding.

When to Utilize Deep Drawing

Deep drawing is most effective with ductile metals. Generally, metals that can be cold rolled into sheets possess sufficient ductility for deep drawing, but other material properties such as work hardening or anisotropy should also be taken into account. Suitable materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and certain stainless steels.

The optimal shapes for deep drawing are rectangles and axi-symmetric structures like cylinders or hemispheres, though the process can accommodate more intricate designs as well.

The tooling and setup costs for deep drawing can vary widely depending on the shape being produced. For straightforward shapes, the costs may be lower than other processes. However, increased complexity results in higher costs. In some instances, these costs can be offset by deep drawing’s minimal downtime, low maintenance, and reduced technical labor requirements over the product’s lifetime. Factors that can elevate complexity include:

- Presence and placement of part features

- Direction of features

- Protrusion of features

- Part size and proportions, including material thickness

Deep Draw operations

In deep draw stamping, various forming operations are often necessary to complete the part. These include:

- Beads, Ribs, and Flanges: These features are frequently used to add rigidity to parts that may otherwise be too flexible or weak. Their strategic use can reduce the required material thickness by up to 50%.

- Bulging: This process involves expanding the walls of a cup, shell, or tube using an internally expanding segmental punch or a punch composed of air, liquids, semi-liquids, rubber, or other elastomers. The expansion can be symmetrical or nonsymmetrical.

- Coining: A closed-die squeezing operation where all surfaces of the work are confined or restrained.

- Curling: Creating a rolled edge at the open end of a part.

- Dimpling: Localized indent forming to allow the head of a rivet or bolt to fasten flush with the metal surface.

- Embossing: A process that creates shallow indentations or raised designs without significantly altering the metal thickness.

- Extruding: Turning up or drawing out a flange around a smaller hole, also known as “hole flanging.”

- Holes: Cutting a shaped portion of metal from the drawn part using conventional, extruding, or piercing punches.

- Ironing: Reducing the thickness of the shell wall and smoothing its surface.

- Marking: Adding identification such as numbers, letters, or graphics to a part.

- Necking: Reducing the diameter of a portion of a cylindrical shell.

- Notches: Shaped notches cut from the edge of the part, usually for clearance, locating, or attaching purposes.

- Threading: Forming threads on a part using a wheel and arbor, tap, or die.

- Trimming: Cutting scrap off a partially or fully shaped part to a specified trim line.

Alternative Manufacturing Processes

In specific situations, alternative processes can be employed to attain comparable outcomes. These include:

Hydroforming: A sophisticated sheet and tube forming technique that utilizes hydraulic pressure, rather than a fixed punch, to create geometries that are not feasible with deep drawing, such as undercut or bulged shapes.

Spinning: This process is suitable for certain axisymmetric parts, where a rotating blank is deformed against a shaped, concentric, rotating mandrel. Typically, tooling costs are lower than those for deep drawing, but cycle times are longer, and setup may necessitate a more skilled machine programmer.

Fabrication: For prototyping or low-volume production runs, parts can be assembled from multiple sheets using welding or other joining methods. Generally, fabrication is only viable when production volumes are insufficient to justify the expense of dedicated tooling.

Deep Drawn Stamping Manufacturer

ChinaCustomStamping are a leading deep drawing parts manufacturer based in China, specializing in the production of high-quality and precision-engineered components. With years of expertise and advanced manufacturing capabilities, we pride ourselves on delivering superior products to meet the diverse needs of our clients. High quality material,100% inspection with QC report,On time delivery

We can custom-made various cylindrical or box-shaped enclosures, cups, and other hollow parts. It involves the use of a punch and die to stretch and bend the metal into the desired shape. Our products are widely used in the production of automotive components, household appliances, aerospace parts, and many other products that require complex, seamless, and precisely formed metal components.

Deep drawing process is an ideal method for creating parts such as cans, cups, enclosures, pans, and various structural components.

Our company have a deep understanding of material behavior, tooling design, and process control to deliver high-quality, precision-engineered components. Quality control measures, including dimensional inspection, surface finish evaluation, and material testing, are crucial to ensuring that the deep drawn parts meet the required specifications and performance standards.

Deep Drawing Ability

Material Available

- Stainless Steel: SS201, SS202, SS303, SS304, SS316 etc.

- Steel: Q235, 20#, 45# etc.

- Brass: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40) etc.

- Bronze: C51000, C52100, C54400, etc.

- Iron: 1213, 12L14, 1215 etc.

- Aluminum: Al6061, Al6063, AL7075, AL5052 etc.

- Plastic:ABS,POM,Nylon,Delrin,etc

- Titanium: TA1/TA2/TB1/TC4/TC18, TI GRADE2/GRADE5

Production equipment

- Stamping Machine (from 5T to 1000T)

- hydraulic press machine

- CNC machining center,

- CNC milling

- drilling machine

- Welding Machine (MIG and TIG welding)

- polish machine

- other equipments

Surface treatment

- Anodizing:color anodizing,hard anodizing

- Plating: Nickel, chrome, zinc plating,powder coating

- Polishing: Electrolytic polishing,mirror polishing

- heat treatment ,sand blasting, Brushing.etc,

- other finish are available as customers’ request

Tolerance

+/-0.1 ~ 0.005mm/as customized

MOQ

50pcs

Qc system

Raw material inspection

Sampling inspection and patrol inspection

100% inspection before shipment

material certification are available upon request.

Other issues

DRW format: pdf/.dwg/.igs./.stp/x_t. etc,almost all 2D or 3D files are acceptable.

Lead time: 7-25 days,depend on quantity

Terms of payment: L/C, PayPal,T/T West Union,etc.50% in advance, 50%before shipment, to be confirmed

Sample: Samples could be arrange prior actual mass production to have everything confirmed by both sides.

Our Services

Our goal: delivering high quality stainless steel deep drawing part with zero defects to all our customers. We intend to meet all the requirements of every design.Our company will use our expertise to reduce your cost for mutual win business.

-

Full experience

We have over 20 years of experience in the field of sheet metal deep drawing.The most favorable processing solutions will be provided based on the customer’s product situation.

-

Strict inspection

From material to final products ,we control very stick for the quality. The material of each lot will be checked. All Final products will be inspected before shipping.

-

Drawing die warehouse

To make sure our quality, all our customer’s deep drawing dies will be well stocked at our factory.

-

Flexible packaging methods

1. Inner Packaging: PP bag, bubble bag, plastic wrap etc.

2. Outer Packaging: carton, wooden case, pallet etc.

3. According to customers’ requirement.

Deep Drawing parts shipping way:

(1).0.5kg-150kg best choice is by Express.

(2). Heavy goods: by sea is available

(3). We can also deliver as client’s requirment

(4). 7-30days after receiving payment/ deposit

(5).Nearest Port:shenzhen Hongkong convenient and efficient transportation

(6).we will choose the cheapest and safest way to shipped the stainless steel deep drawing part.

Ask a free quote

In order to quote you as son as possible please provide us the following information:

1) Detail drawings(CAD / PDF/ DWG/ IGS/ STEP)

2) Material

3) Quantity

4) Surface treatment

5) Any special packing or other requirements

6)Target price if you have

All services we offer

We are professional manufacturer,which mainly offer OEM / ODM service of Metal stamping parts,deep drawn enclosure,CNC machining parts,Wire forming parts.