Basic Requirements and General Steps of Stamping Die Design

2.1 Basic Requirements and General Steps of Stamping Die Design

2.1.1 Required Information for Stamping Die Design

- Drawings and technical requirements of the component (also known as stamped part or workpiece).

- Stamping process card and production batch of the component.

- Model and specifications of available press machines, especially parameters related to die installation and force capabilities.

- Relevant technical standards, such as material standards, tolerance and limit standards, standard die components, mechanical drawing standards, etc.

- Technical information, such as practical handbooks for stamping mold design, mold structure diagrams, typical structural data, guiding die technical information specified by the industry, and company design specifications.

2.1.2 Basic Requirements for Stamping Die Design

- Stamping dies design is a crucial aspect in ensuring the quality of stamped parts, particularly in industries such as automotive, aerospace, instrumentation, household appliances, electronics, telecommunications, military, toys, and daily necessities. Stamped parts have high requirements for process control and quality, imposing strict demands on die design. Die designers should be proficient not only in mold design specialization but also in sheet metal design, stamping processes, metallic materials and heat treatment, and stamping equipment.

- The mold design should adhere to three fundamental principles: safety, advancement, and economy. Additionally, designers should consider the actual conditions of their own company (or collaborating companies), including existing equipment, process levels, and machining equipment, in order to comprehensively consider and design dies that are structurally reasonable, economically applicable, and guarantee the produced components meet the shape and size requirements specified in the drawings.

- The designed die should strive for simplicity in structure, convenience in operation, long service life, secure and reliable function, low cost, ease of manufacturing and maintenance, while ensuring the produced components meet the shape and size requirements specified in the drawings.

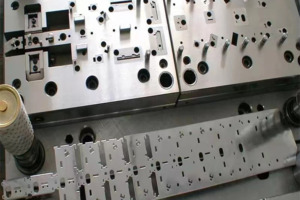

- Stamping mold come in various types, with different structural forms, design methods, and considerations. The structure characteristics of dies used for different components or equipment may vary. Therefore, die design must be tailored to the specific requirements of use.

Professional Metal Stamping Manufacturer in China

As a professional metal stamping manufacturer in China, we take great pride in providing high-quality products at competitive prices. Our commitment to excellence and our focus on customer satisfaction set us apart from other manufacturers in the industry.If you need stamping part to be produced or need stamping dies to be made,please contact us. We can offer high quality with low cost to save time and money for your new project.