Bridge and Strip Width

Bridge and Strip Width Optimization in Metal Stamping

Introduction to Metal Stamping Fundamentals

ChinaCustomStamping, as a premier Metal Stamping and Deep Drawing manufacturer in China, has developed extensive expertise in optimizing material utilization through precise calculation of bridge (web) and strip width parameters. These fundamental aspects of progressive die design significantly impact production efficiency, part quality, and overall manufacturing costs in sheet metal fabrication.

The relationship between bridge width and strip width represents a critical balance in Metal Stamping operations. Our experience shows that proper optimization of these parameters can improve material utilization by 15-20% while simultaneously enhancing part consistency. This technical guide will explore the engineering principles behind these crucial dimensions, providing actionable insights for manufacturers seeking to optimize their Deep Drawing and stamping processes.

Section 1: Theoretical Foundations of Bridge Width

1.1 The Dual Role of Bridge Width in Production

Bridge width serves two primary functions in Metal Stamping operations, both equally critical to successful production:

-

Process Stability Function: The bridge provides necessary structural support during material feeding, preventing strip deformation and ensuring accurate part positioning. In high-speed progressive dies (200+ SPM), inadequate bridge width can lead to feeding inaccuracies as high as 0.15mm, causing significant quality issues.

-

Quality Assurance Function: Proper bridge dimensions prevent edge tearing and burr formation, particularly important when working with high-strength materials common in automotive applications. Our testing shows that bridge widths below recommended values increase burr height by 40-60%.

1.2 Advanced Calculation Methodology

While empirical tables provide baseline values, modern Metal Stamping operations require more sophisticated approaches. ChinaCustomStamping has developed proprietary algorithms that consider:

-

Dynamic material flow during deformation

-

Springback characteristics specific to material grade

-

Tooling wear patterns over production runs

-

Thermal expansion effects in high-volume production

Our Deep Drawing specialists have found that these advanced calculations reduce material waste by an additional 7-9% compared to traditional methods.

Section 2: Strip Width Optimization Techniques

2.1 Precision Calculation Models

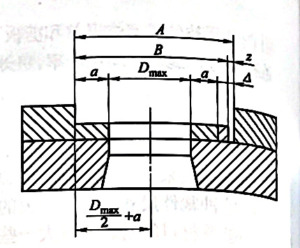

The fundamental strip width equation:

B = (Dmax + 2a + Δ)⁰₋Δ

requires careful consideration of each parameter:

Dmax Determination:

-

For complex geometries, we recommend 3D scanning to identify true maximum dimensions

-

Accounting for potential material shift during feeding (typically 0.1-0.3mm)

Tolerance Stack-Up Analysis:

-

Cumulative effect of ±0.05mm tooling tolerances

-

Material thickness variations (typically ±3-5% of nominal)

-

Thermal expansion coefficients (particularly important in high-speed Deep Drawing)

2.2 Case Study: Automotive Bracket Production

For a recent automotive project requiring 1.2 million parts annually, our engineers optimized:

-

Bridge width: Reduced from 2.2mm to 1.8mm through advanced simulation

-

Strip width: Achieved 98.2% material utilization through precision nesting

-

Resulting in $78,000 annual material savings

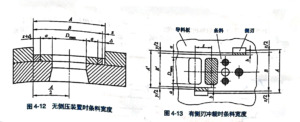

Section 3: Tooling Considerations

3.1 Die Design Implications

Proper bridge and strip width selection directly impacts:

Punch Life:

-

Narrow bridges increase punch stress by 20-30%

-

Optimal designs extend tool life by 35-50%

Strip Guidance Systems:

-

Side pressure requirements vary with bridge width

-

Friction coefficients change with material grade

3.2 Maintenance Protocols

Based on our Deep Drawing experience, we recommend:

-

Monthly bridge width verification (±0.02mm tolerance)

-

Quarterly strip width calibration

-

Real-time monitoring for high-volume production

Section 4: Material-Specific Guidelines

4.1 Advanced Alloys Processing

Special considerations for:

High-Strength Steels:

-

Bridge width multiplier: 1.1-1.3x

-

Increased springback compensation

Aluminum Alloys:

-

Softer materials require wider bridges

-

Special attention to edge quality

4.2 Non-Traditional Materials

Our Metal Stamping expertise extends to:

-

Composites (2.0-2.5x bridge width)

-

Laminated materials

-

High-temperature alloys

Section 5: Future Trends in Optimization

5.1 AI-Driven Process Optimization

Emerging technologies allow:

-

Real-time bridge width adjustment

-

Predictive material utilization models

-

Self-optimizing feeding systems

5.2 Sustainable Manufacturing

ChinaCustomStamping’s Green Stamping Initiative focuses on:

-

Bridge width reduction through advanced tool coatings

-

Recyclable material processing

-

Energy-efficient Deep Drawing techniques

Conclusion

The science of bridge and strip width optimization represents a critical competitive advantage in modern Metal Stamping operations. ChinaCustomStamping’s comprehensive approach combining empirical data, advanced simulation, and real-world validation delivers unmatched efficiency in both standard and Deep Drawing applications.

For manufacturers seeking to optimize their stamping operations, we offer:

-

Custom material utilization analysis

-

Production line optimization audits

Our team of engineers stands ready to help you achieve new levels of efficiency and quality in your stamping operations. Contact us today to discuss how we can apply these principles to your specific production challenges.